Irish Owned

We Specialise in the Installation and Maintenance of Automatic Lubrication Systems

Automatic Lubrication Systems

If you have any questions about any of the products you see for sale on our site, or our lubrication

and services side of our business you can contact us by using the email form on the right, or by calling us on:

What is an Automatic lubrication system?

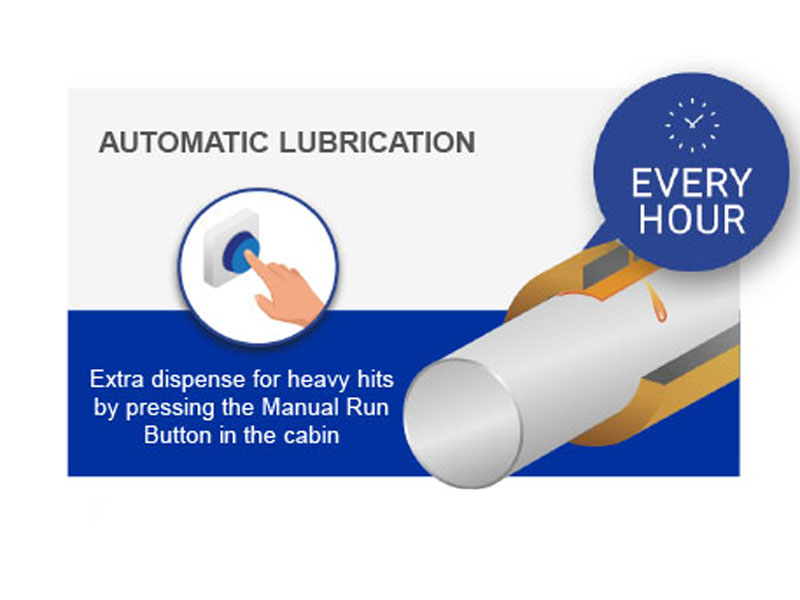

An automatic lubrication system automatically provides your equipment with the right amount of lubricant at the right time and in the right place — while the machine is in operation. It replaces a conventional lubrication system such as a grease gun. An automatic lubrication system reduces both maintenance and costs and eliminates downtime.

1. Why lubrication

6 Major Reasons

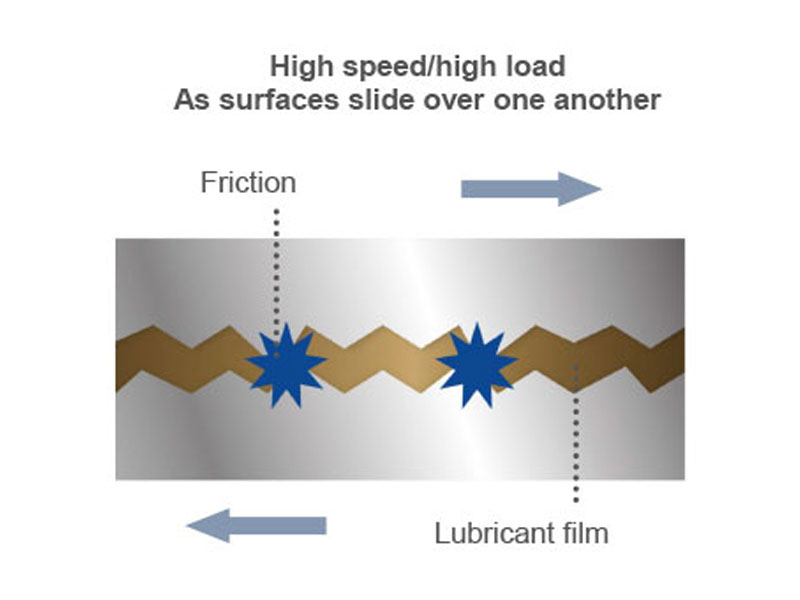

- Reduce friction

- Reduce wear

- Absorb shock

- Reduce hear

- Minimize corrosion

- Seal out contamination

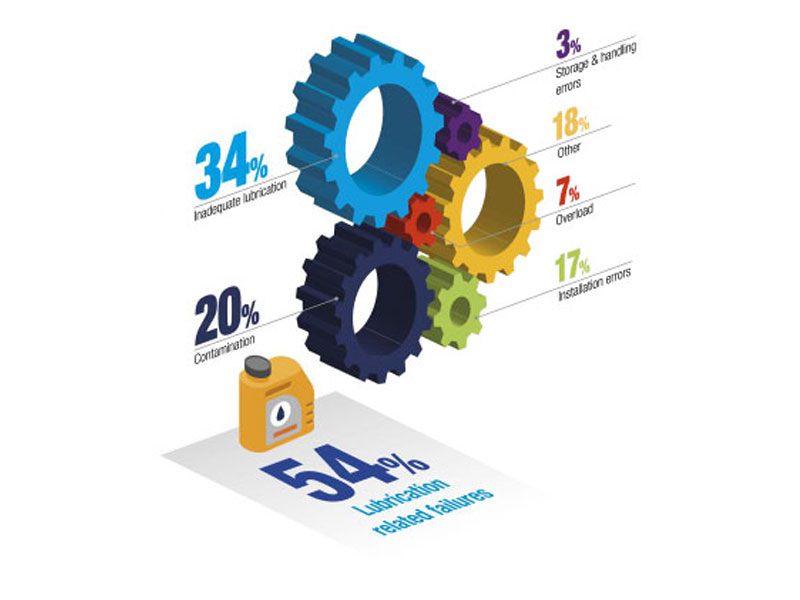

More than 50% of bearing failures are the result of improper lubrication.

Effects of a bearing failure:

- Costs of new bearings

- Loss of production due to downtime

- Labor costs for the repair

- Safety risks when repairing

- Missed customer deliveries

2. Why bearings fail

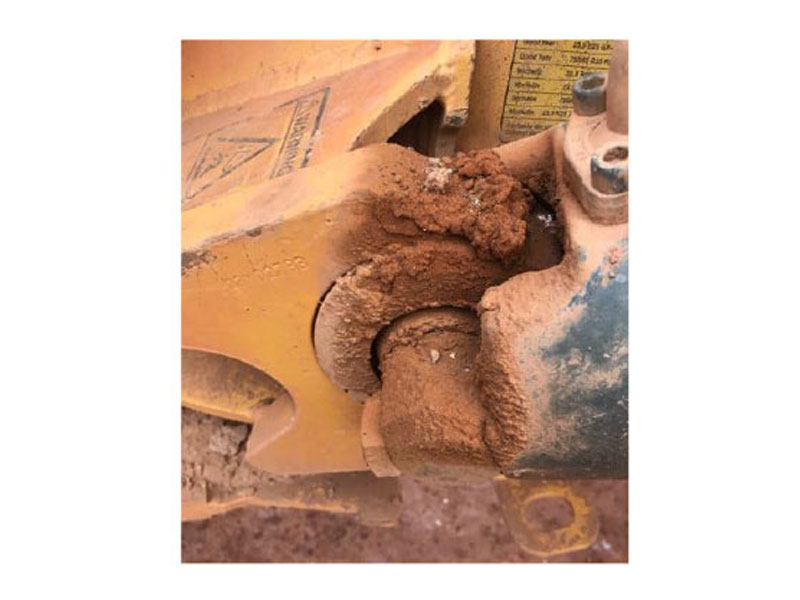

Contamination, the pitfall of manual lubrication

- Open lube points lack fresh grease

- Dirt can easily enter the system

Dirty grease zerks

- Dirt will be pushed into lubrication point

- Dirt will act like an abrasive

- Premature failure of the bearing or bushing

2. Why bearings fail

Heavy duty machinery and equipment require proper lubrication

- Accurate lubricant dosing

- At regular intervals

- In the right place

- Lubricate while machine is running

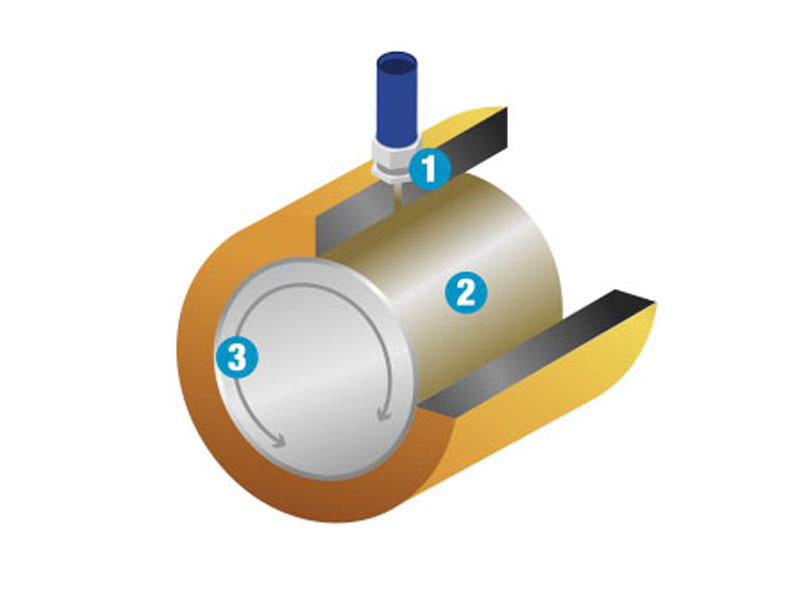

3. How does an automatic lubrication system work?

- The pump and reservoir store and provide a steady flow of lubricant.

- The time- or cycle-based controller activates and monitors the system

- Metering devices such as injectors or series progressive divider valves accurately dispense the right amount of lubricant to the lubrication points.

- The hose and fittings transport the lubricant from the reservoir to the metering device, from the metering device to the bearings and other vital parts of the machine.

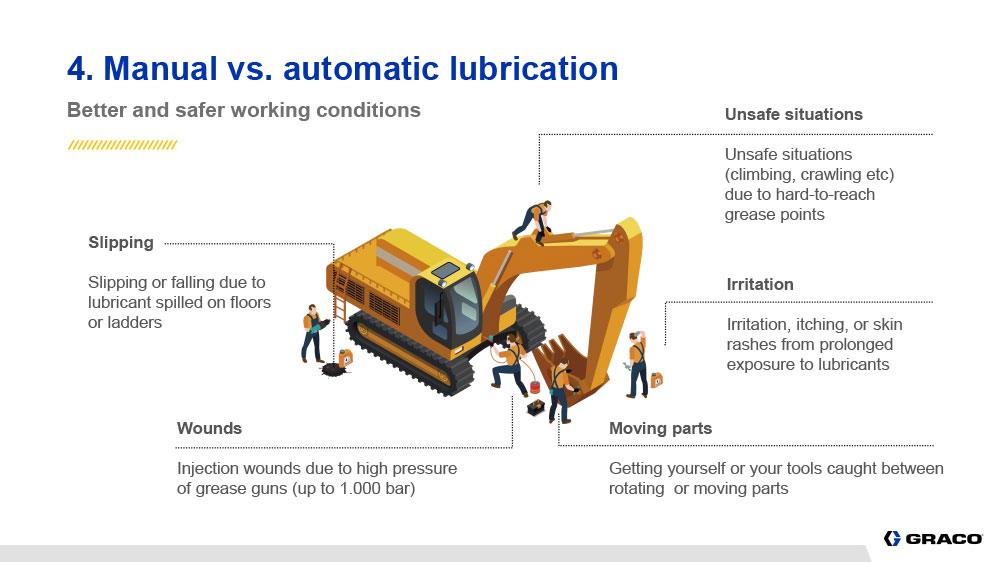

4. Manual vs. automatic lubrication

Manual lubrication has a number of shortcomings:

- Increased machine downtime

- High maintenance costs

- Unsafe working conditions

- Inconsistent lubrication

An automatic lubrication system results in:

- Extended equipment lifetime

- Less downtime and higher productivity

- Better and safer working conditions

- Reduced costs and higher ROI

4. Manual vs. automatic lubrication

Automatic lubrication leads to extended equipment lifetime

- It consistently dispenses accurate doses of lubricant.

- It enables the permanent purging of contamination while the system is working.

- The entire pin is coated, and equal purging of the pin’s circumference is obtained.

4. Manual vs. automatic lubrication

Automatic lubrication leads to higher productivity

- Automatic lubrications systems consistently dispense accurate doses of lubricants.

- Lubrication is done while the machine is running. No shut down required

-

Without proper lubrication, the effects of friction and contamination can be severe.

-

This compromises the lifetime of the equipment and increases frequency of repair and operation downtime.

4. Manual vs. automatic lubrication

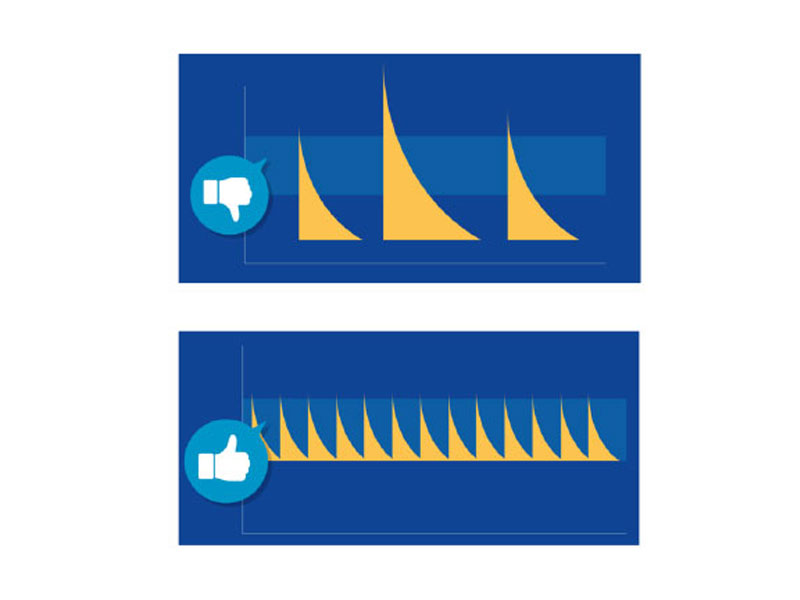

Avoid losses due to shock loading

Shock loading affects pins and bushings

With every hit the grease between the pin and bushing is squeezed out, creating metal-to-metal contact

4. Manual vs. automatic lubrication Avoid losses due to shock loading

Avoid losses due to shock loading

Constant lubrication keeps the bushings and frame in perfect condition

Microwelding wears out bushings and affects the frame

- A refiller needs to climb a ladder or stairs with a fill hose.

- By carrying a hose, the refiller loses the use of one hand.

- Automatic fill shut-off and ground-level refilling options.

- A single person can safely refill the reservoir at ground level.