Lubrication

What is a Lubrication System – HLS Explains

What is a Lubrication System – HLS Explains

What is a lubrication System? A Lubrication system is a means whereby a material is placed between two rubbing surfaces to alleviate friction and therefore wear. For example if you rub your hands together they will heat up due to the friction and eventually your skin will burn. However, if you put soap your hands you will reduce the friction and therefore stop the damage.

The same applies for all surfaces which rub together and if there is no lubrication in moving metal machinery, it means parts being replaced, and regularly in fast moving machines like vehicles, manufacturing equipment, pistons, pumps, cams, bearings, turbines, cutting tools, chains, and motors.

To help stop this wear a substance called a lubricant, is put in between the surfaces to carry or to help carry the load. The lubricant is most commonly an oil or a grease. Keeping the lubricant between moving surfaces is difficult to do and that’s where a lubrication system comes in.

Depending on the application a different lubrication system is used

Heavy Machinery

Larger machinery such as diggers, trucks, tractors, with many moving parts, more than the engine requires regular lubrication. The bearings work under heavy load, in dirty wet conditions and all the pivoting points on the hydraulic arms need to be kept sufficiently lubricated.

So what is a Lubrication System on a JCB? Well there isn’t one, all these points have to be lubricated manually. After every few hours of work the driver has to go to up to 30 points and pump in some grease.

We can install an Automatic lubrication system. Our Automatic Lubrication Systems can grease machines of any size. We put a tried & trusted Lincoln pump with a suitably sized reservoir, that injects grease to all the points that require it.

These Auto Greasers do it on a strict schedule meaning a lubrication cycle is never missed leading to part failure and breakdown.

Want to know more. We have extensive information on all our Automatic Lubrication Systems at www.hls.ie/services/automatic-lubrication-systems

The lubricant in these parts are most commonly a grease. Greases are much thicker than oil and harder to move, but last much longer and lubricate better than oil.

There are different greases for different applications. Such as Extreme Pressure (EP2) Grease, High Temperature Grease, Water Resistant Grease or even FLM2 Grease with Molybdenum disulphide for extreme conditions.

Heavy Industry

Large factories or other places with large industrial machines also require similar greasing. But they also have the complication of needing other items kept lubrication. Chains, gears or rails can wear or jam without being kept constantly greased.

This where our Automatic Lubrication System is used as well. From a single pump the grease pipes pump grease to bearings, or to a chain lubrication brush, a spray for rails, or a special gear that secretes lubrication onto a gear’s face evenly.

Once again much more information can be found at www.hls.ie/services/automatic-lubrication-systems for specific systems used in specific situations.

Engine Lubrication Systems

Whats is a lubrication System on my car? A combustion engine has so many moving parts that it requires quite a complicated lubrication system, but still only requires the owner to keep one single tank of lubricant topped up.

The Lubricant used in car engines is engine oil, sold in many places, most commonly in 5 to 10 litre containers. Modern Car engines, made on very strict tolerances require a very specific engine oil. The exact oil used for each car can be found in the vehicles manual.

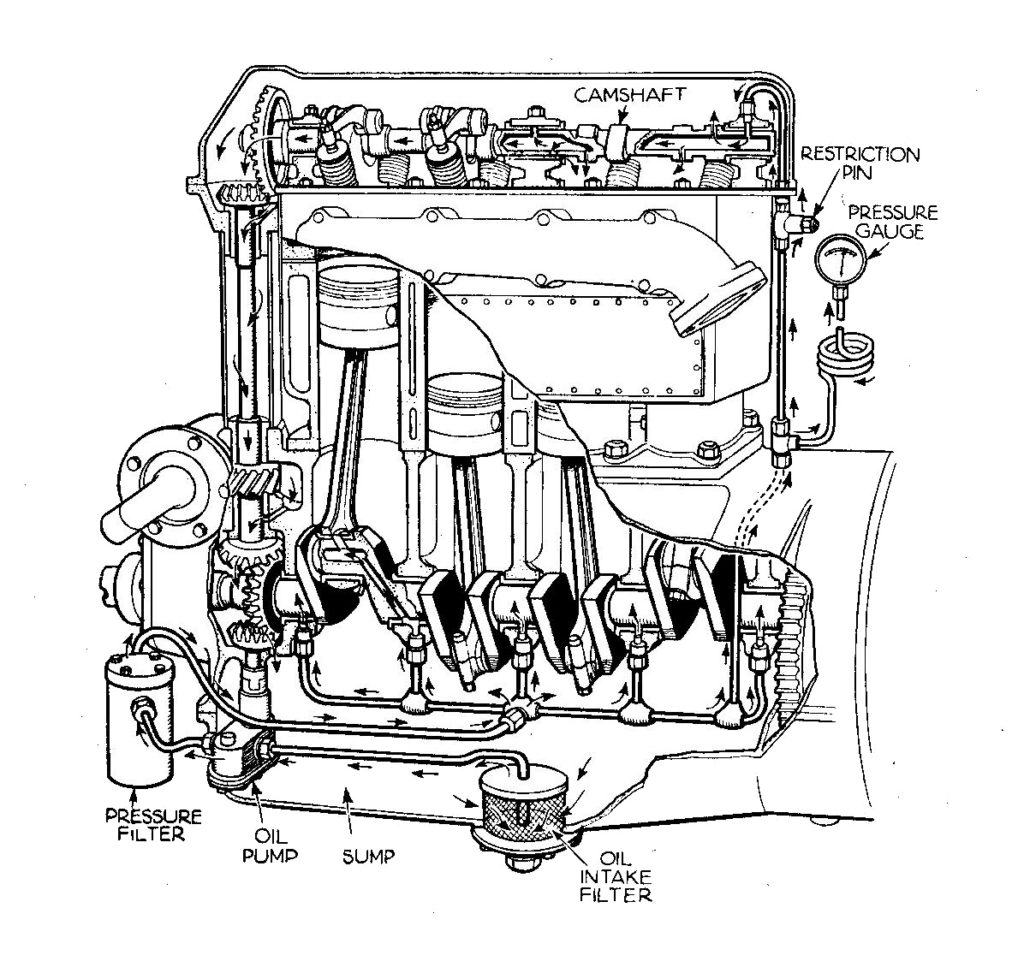

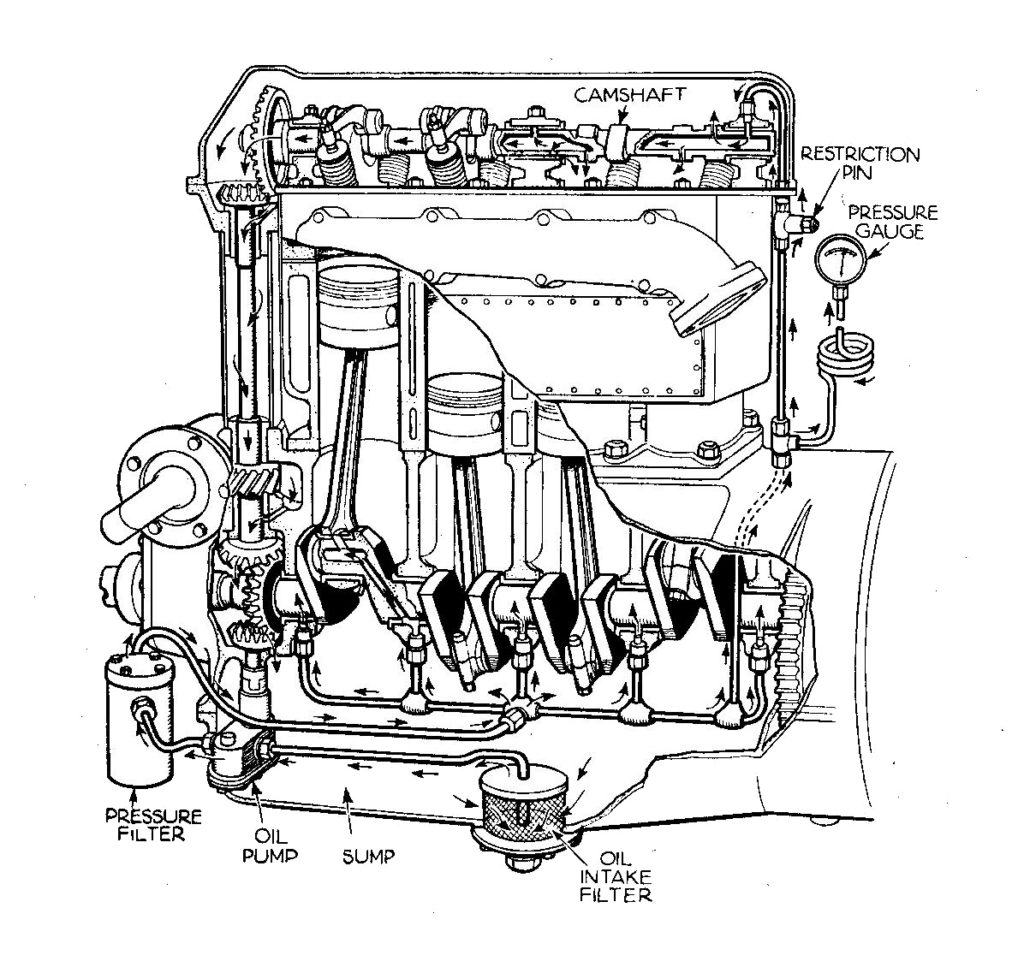

Engine Lubrication systems start in the oil tank, also called the oil sump. From here the engine oil is sucked up by the oil pump and pumped on through the oil filter to remove anything floating in it. It is then pumped to all the bearings and through the camshaft (the spinning rod at the top of the engine) and the crankshaft (the rail at the bottom of the engine). There are then holes in these two rods from which the oil sprays and falls over the cams and moving engine parts keeping them lubricated. The unused oil then falls back into the oil sump at the bottom to be filtered and reused.

Two Stroke engines have a far simpler lubrication system to keep the weight down in hedge cutters, lawnmowers and boat engines. The air-fuel mixture is simply allowed flow all over the pistons in the engine. An additive is then added to the fuel, this is the lubricant, this allows the air-fuel mix to lubricate all the moving parts as it flows through the engine. This additive is commonly called two stroke mix as it’s mixed with the fuel prior to filling up the machine.

Alongside ensuring a well-functioning lubrication system, other maintenance tasks like DPF cleaning are crucial for the longevity and efficiency of your engine. Learn more about our heavy machinery DPF cleaning services.